The Quarion Platforms

Coming in mid-2025, the Q-TABLET Platform uses Quarion’s hardened operator interface tablet. Q-Tablet can mount as a dedicated device on any brand of forklift, most kinds of other powered industrial vehicles or can be used as an independent handheld device.

Quarion’s first Q-TABLET Application is Q-Check, an Operator Safety Checklist, for compliance with the OSHA 29 CFR 1910.178 pre-operation safety inspection standard. Q-check makes managing and documenting compliance simple and reliable for almost any type and brand of powered industrial vehicle in your facility.

Q-TABLET can be used as a handheld device for inspection of multiple machines or mounted as a dedicated device.

Dedicated devices can be paired with Quarion’s Q-Pedal module to dead pedal machines until they have been inspected and acknowledged to be safe.

Dedicated Q-Tablets can be used on the ATLAR 5D Platform to alert service personnel with the precise location of machines failing inspection.

Quarion is searching for development partners to guide the development of other APPS – If you need an application let’s talk soon.

Quarion offers the Q-RF platform as a simpler, though less precise, approach to indoor GPS which elegantly solves a narrower range of vexing problems.

Q-RF utilizes Radio Frequencies broadcast by directional antennas. Q-RF does not calculate a location but transmits a control signal into an area. A machine mounted receiver senses the radio signal when entering that area, allowing enforcement of speed limits or denial of access through the Q-RF machine control interface.

The simplicity of Q-RF makes it an ideal entry level solution, allowing design, installation and commissioning with minimal training, effort and expense.

Quarion’s Q-RF platform includes a cost effective upgrade path to ATLAR 5D with the reuse of most of the customer’s investment in Q-RF components.

The ATLAR 5D Platform in simplest terms replicates the functions of the Global Positioning System (GPS) but in indoor spaces.

ATLAR 5D infrastructure begins with a network of Quarion’s “satellite” Q-hubs within a provisioned space. The precise locations of the Q-hubs is determined at installation. Knowing their locations allows the ATLAR 5D software layer to calculate the location of Quarion transceivers with a precision as small as centimeters and as often as 20 times per second.

ATLAR 5D infrastructure begins with a network of Quarion’s “satellite” Q-hubs within a provisioned space. The precise locations of the Q-hubs is determined at installation. Knowing their locations allows the ATLAR 5D software layer to calculate the location of Quarion transceivers with a precision as small as centimeters and as often as 20 times per second.

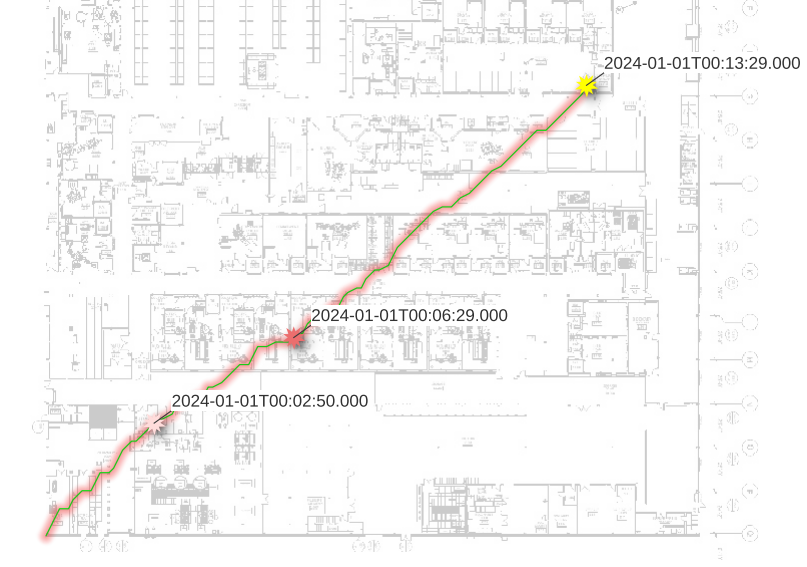

ATLAR 5D not only knows the time and location, but the speed, heading, and direction of tracked objects. A wide range of additional sensors can be incorporated to extend data collection linked to location. In common ATLAR 5D configurations, 100 or more data variables are logged, up to 20 times per second, for every tracked object.

In the case of powered industrial vehicles like forklifts, ATLAR 5D can also read and record the traffic on the vehicle’s CANBUS control network, opening the ability to monitor granular data about a machine’s operation and performance.

Quarion currently offers two machine controllers. One is a speed control interface, the other a Throttle on/off controller.

The ATLAR 5D software layer can communicate rules based instructions back to tracked machines to “dead pedal” the throttle or limit the maximum speed of the machine. This bi-directional communication and control allows precise geofencing of areas with speed limits or access control/denial.

ATLAR 5D also keeps managers informed in real time of incidents though its SMS and e-mail interfaces.

Quarion’s ATLAR 5D platform is a system solution tailored to the needs of the customer and the physical space being provisioned.

ATLAR 5D Solution Examples

ATLAR 5D Data

Tabular Reports

Every ATLAR 5D system includes a set of tabular reports customized for the customer’s needs. The reports are generated on the customer’s schedule and can be distributed to managers via e-mail or SMS distribution lists.

Visualizations

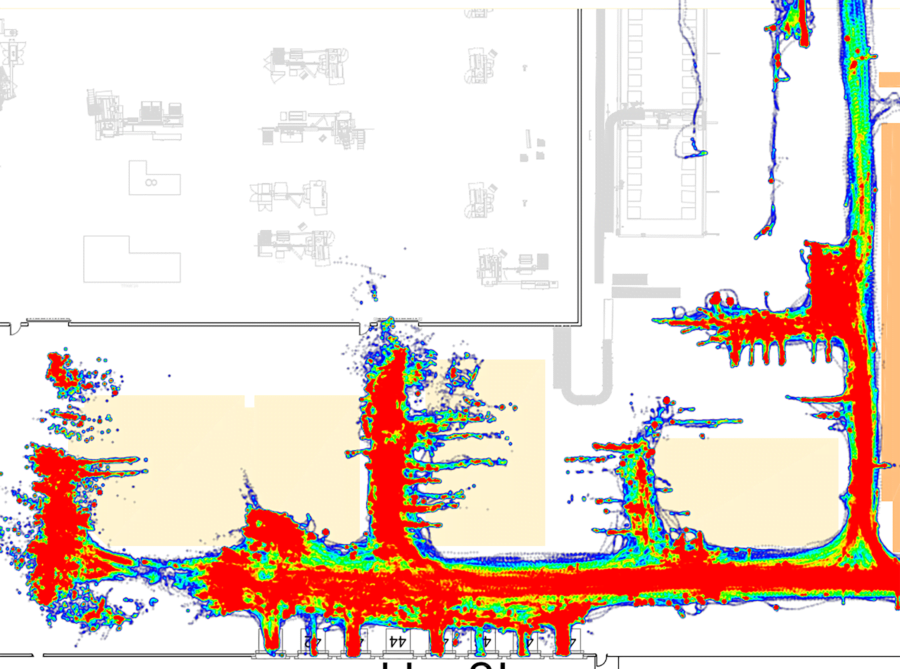

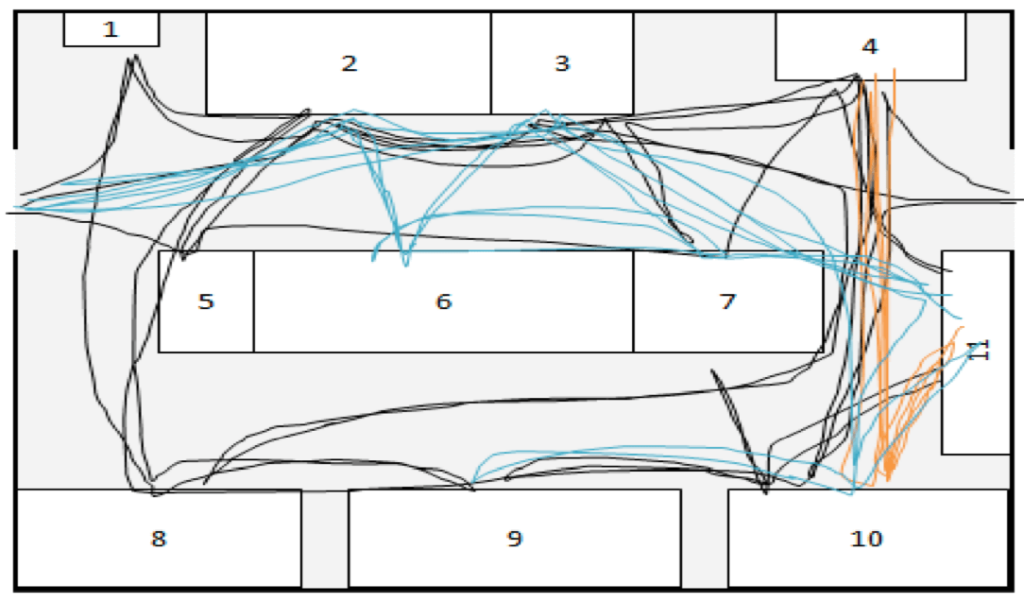

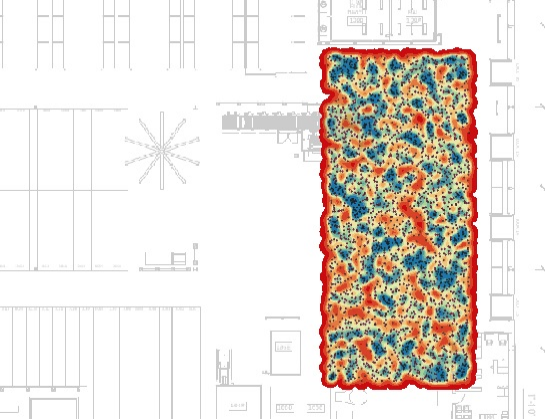

ATLAR 5D systems can include heat mapping and spaghetti diagramming visualizations

Q-LYTIX (Coming 2025)

Q-LYTIX is Quarion’s solution for opening ATLAR 5D data to the customer’s favorite Business Intelligence and Visualization tools. Under development for delivery in 2025 – seeking development partners.

Q-GIS (Coming 2025)

Q-GIS allows overlay Visualizations of location linked data on the floorplan of the customer’s facility based on standard SQL queries. Under development for delivery in 2025 – seeking development partners.

Q-ML (Coming 2025)

Quarion’s ATLAR 5D platform generates data sets which are not only massive but relevant and clean.

For an interesting perspective on the machine learning potential of Forklift Location Data Sets check out thIS Clip featuring Walker Reynolds and Jordan Reynolds.

Quarion is looking for development partners Ready to Explore Material Handling training sets for Machine Learning.

If that Sounds Like you…Let’s Talk